Industrial applications require components that offer many years of use. Sustainability is vital in these environments, and the wrong products won’t achieve all the company’s objectives. Hose and cable carriers provide adequate protection for machines and equipment in manufacturing and industrial spaces. Find out more details about using cable and hose carriers for industrial machines and equipment and how the carriers improve your applications

Protect Cables and Hoses Connected to Your Machines

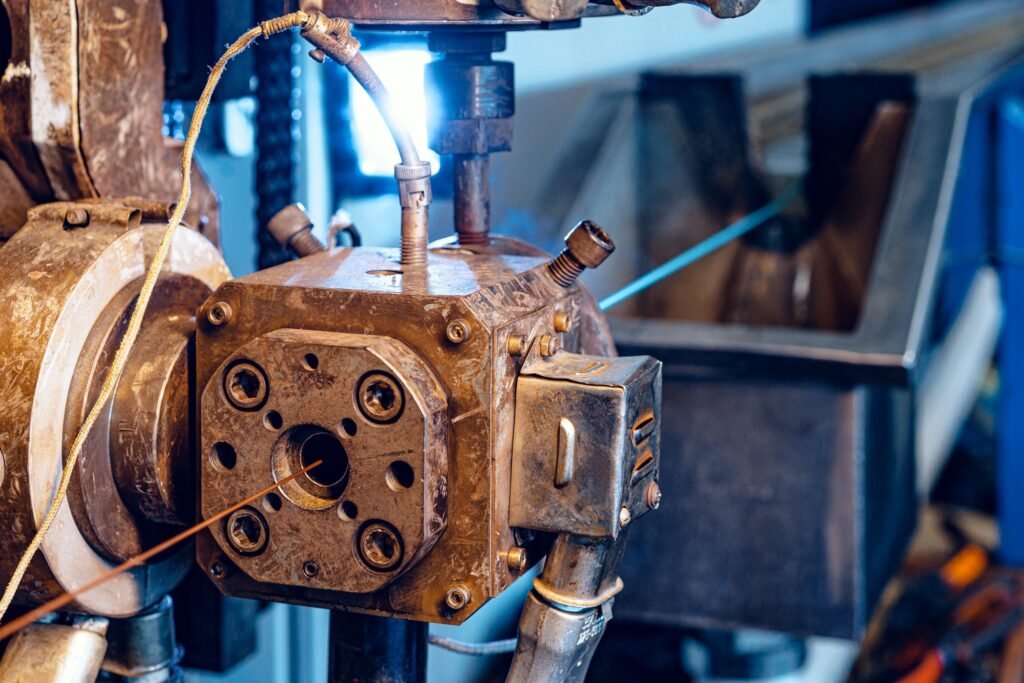

In industrial spaces, business owners need better protection for cables and hoses connected to machines. Loose components could create quite a problem and increase friction in the equipment. Using a cable and hose carrier lowers these risks and protects the equipment for many years. These products give workers more control over the equipment and prevent sudden damage that leads to slowdowns in production and profits.

Lowering the Personal Injury Risks to Workers

Employers must follow all measures to keep their workers safe in industrial environments and stop anyone from being injured. Hazards in the workplace increase the risk of worker’s compensation claims and financial losses for the company. Workers won’t become injured or face serious personal injury risks if the equipment has the right carriers installed, and the businesses improve the way the organizations operate.

Increasing the Speed and Travel for Equipment

Industrial environments require equipment to move parts and products throughout the workplace at great speed and with precision. Carriers improve the way these machines work and keep parts and products moving around the space safely and without causing damage. These carriers lift and move items to different spaces in the facility and reduce accidents that result in damaged products or equipment.

Improved Durability for the Equipment

Proper carriers improve the durability of the equipment and machines. As they move, the materials do not rub together and break or tear. These carriers adjust the machines for workers quickly and speed up operations without creating safety risks. These new installations increase the durability of the equipment over the years and prevent unnecessary wear to a variety of parts.

Do Not Need Regular Lubricant Applications

Carrier designs feature parts manufactured with an oil base to make them self-lubricated, which reduces maintenance requirements for the equipment. The carriers do not require lubrication frequently to stop corrosion and reduce friction. The overall design is safer and cuts down on extra tasks for the maintenance staff.

Sustainable Products for All Industrial Applications

More manufacturers are using the carriers with their equipment and machines since the products are more sustainable than similar applications. Business owners can get higher quality materials such as stainless steel that is strong and won’t break or damage products traveling throughout the factory or facility.

Businesses such as manufacturing plants need strong applications to create products and set up automated processes, and carriers are a terrific option for moving items throughout the space safely and without damage. Exploring these options could give a manufacturer everything they need in their factory to mass produce products and speed up these processes. Talk to suppliers about cable and hose carriers for your business.