Plastic mold technology has come to be considered plastic molding technology in recent times. Interestingly, there is a process that has been going on since 1872. At the same time, it is common processing and it is for the production of mass plastic parts and is often better than other processes (is it interesting). The question that may come to your mind is why is it good for mass production of plastic parts? Well, let me explain it.

This is due to its tough tolerance to producing economically complex plastic products. However, you need to keep in mind that it is best to choose something suitable for any plastic part. At the same time keep in mind that often a plastic mold is a very complex process. However, you must be designed and manufactured by an expert plastic mold maker.

What is plastic mold and molding technology?

You already have an idea of how complex a plastic molding is. This is because at the same time there are many requirements imposed by the plastic injection molding process. However, in this episode let’s take a look at the simple steps to making a plastic mold.

- Create a part designer’s desired model design. Or hire your supplier to design the model according to your needs.

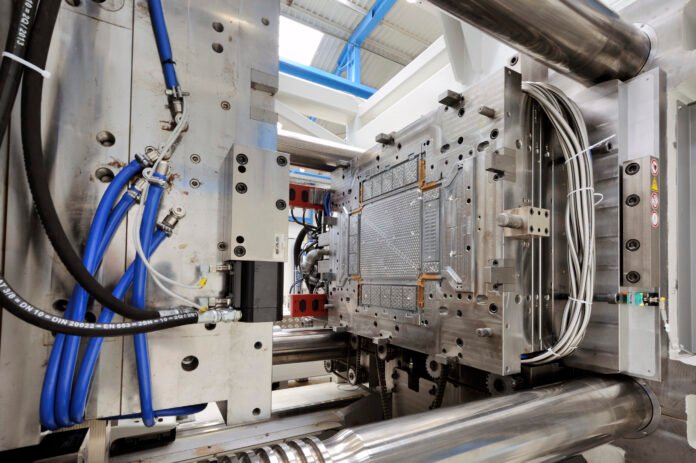

- Then the design of that part will be approved, then you find your mold supplier with a complete mold design. When the mold design is complete, you can start making plastic molds. In this case, one has to take ideas about drilling, EDM, CNC machining, and polishing including the plastic mold manufacturing process.

- You will need to do the mold fitting in the last step of making the plastic mold. In this case, you need to make sure that when the mold is finished, the components are in the correct position. And to do this you can of course fit the mold. The question that may come to your mind is what is mold fitting? The answer is simple, the only way to test and improve it.

- When you notice that the mold fitting is finished, you need to start the actual injection molding process. Remember to do the mold trial at the beginning of the injection molding process. And to get mass production from mold trials, you have to go through some time. In this case, try the mold several times. As a result, you’ll be able to figure out if there are any problems with the first mold trial and whether you need to finish.

Try the two molds several times to get the samples for customer approval. Then you can start mass production. Not only that, to get the perfect finished plastic products to get a simple working method to explain mold design, part design, and mold production. Experts believe that plastic molding technology is still not something that most people need to know about.

The Mould Supplier’s basic Guide

What will 2022 look like? It’s anyone’s guess, but here are some ideas we had while brainstorming what The mold supplier could offer our readers in 2022. This list has been so popular that it has actually spilled over into 2023 and 2024 too! Some of these tips may seem obvious and you might wonder why we’re even writing about them, but as someone who used to have trouble growing mould, we think it’s important to write about the basics sometimes.

Top mould suppliers

The first step for any business is finding clients, and for most businesses in need of custom moulds, that means searching online or through industry contacts. The following companies all make regular appearances on lists of top mould suppliers: Janicki Industries, KG Precision Tooling and Valmold Technologies. Each company has various branches or subsidiaries throughout North America, Europe and Asia-Pacific; they provide one-stop shopping for many customers because they manufacture not only molds but injection molds and other machinery as well.

In conclusion, you may be happy to know that most people in the world are using products that are made using this method (which isn’t great news). For example bottle caps, home appliances, furniture components and accessories, bicycle accessories, cooking utensils, automobile plastic parts, cosmetic molding, and packaging containers, toys, medical plastic parts. Not only this, with the help of mold and plastic molded parts you can get things like construction parts.